30KW High Frequency Split Induction Heating Equipment (GY-30AB)

What is Induction Heating?

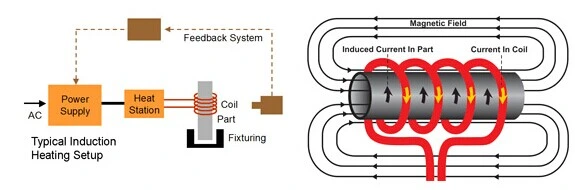

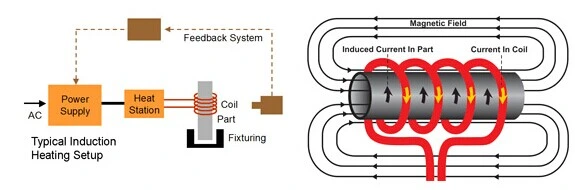

Induction heating is the process of heating an electrically conducting object (usually a metal) by electromagnetic induction, where eddy currents (also called Foucault currents) are generated within the metal and resistance leads to Joule heating of the metal.

An induction heater (for any process) consists of an induction coil (or electromagnet), through which a high-frequency alternating current (AC) is passed. Heat may also be generated by magnetic hysteresis losses in materials that have significant relative permeability.

The frequency of AC used depends on the object size, material type, coupling (between the work coil and the object to be heated) and the penetration depth.

High Frequency Induction heating is a process which is used to bond, harden or soften metals or other conductive materials. For many modern manufacturing processes, induction heating offers an attractive combination of speed, consistency and control.

The basic principles of induction heating have been understood and applied to manufacturing since the 1920s. During World War II, the technology developed rapidly to meet urgent wartime requirements for a fast, reliable process to harden metal engine parts. More recently, the focus on lean manufacturing techniques and emphasis on improved quality control have led to a rediscovery of induction technology, along with the development of precisely controlled, all solid state induction power supplies.

What makes this heating method so unique? In the most common heating methods, a torch or open flame is directly applied to the metal part. But with induction heating, heat is actually "induced" within the part itself by circulating electrical currents.

Induction heating relies on the unique characteristics of radio frequency (RF) energy - that portion of the electromagnetic spectrum below infrared and microwave energy. Since heat is transferred to the product via electromagnetic waves, the part never comes into direct contact with any flame, the inductor itself does not get hot , and there is no product contamination. When properly set up, the process becomes very repeatable and controllable.

Delivery Time: within 25 workdays.

Shipping Term:By sea,By air,by express.

Extra accessories accept choose,

1>Chiller

2>Customer design Coil Box

3>Infrared Thermometer

4>Back-up Electronic Boards

5>Forging Furnace(Depends on Heating rod size customs design)

Work Principle

Application Photo

What is Induction Heating?

Induction heating is the process of heating an electrically conducting object (usually a metal) by electromagnetic induction, where eddy currents (also called Foucault currents) are generated within the metal and resistance leads to Joule heating of the metal.

An induction heater (for any process) consists of an induction coil (or electromagnet), through which a high-frequency alternating current (AC) is passed. Heat may also be generated by magnetic hysteresis losses in materials that have significant relative permeability.

The frequency of AC used depends on the object size, material type, coupling (between the work coil and the object to be heated) and the penetration depth.

High Frequency Induction heating is a process which is used to bond, harden or soften metals or other conductive materials. For many modern manufacturing processes, induction heating offers an attractive combination of speed, consistency and control.

The basic principles of induction heating have been understood and applied to manufacturing since the 1920s. During World War II, the technology developed rapidly to meet urgent wartime requirements for a fast, reliable process to harden metal engine parts. More recently, the focus on lean manufacturing techniques and emphasis on improved quality control have led to a rediscovery of induction technology, along with the development of precisely controlled, all solid state induction power supplies.

What makes this heating method so unique? In the most common heating methods, a torch or open flame is directly applied to the metal part. But with induction heating, heat is actually "induced" within the part itself by circulating electrical currents.

Induction heating relies on the unique characteristics of radio frequency (RF) energy - that portion of the electromagnetic spectrum below infrared and microwave energy. Since heat is transferred to the product via electromagnetic waves, the part never comes into direct contact with any flame, the inductor itself does not get hot , and there is no product contamination. When properly set up, the process becomes very repeatable and controllable.

Parameter:

Model | GY-30AB (Three phase) |

| work power | 340V-430V |

| input current | 31A |

| Fluctuating output power | 30KW |

| fluctuating frequency | 30-80KHZ |

| output current | 300-1500A |

| the flow rate of cooling water | 0.08-0.16Mpa 7.6L/Min |

| water temperature protection point | 40C |

| product size | main :640x260x520 mm |

| transformer : 440x260x410 mm | |

| net weight | main : 26.5 kgs |

| transformer : 20.5 kgs |

Shipping Term:By sea,By air,by express.

Extra accessories accept choose,

1>Chiller

2>Customer design Coil Box

3>Infrared Thermometer

4>Back-up Electronic Boards

5>Forging Furnace(Depends on Heating rod size customs design)

Work Principle

Application Photo