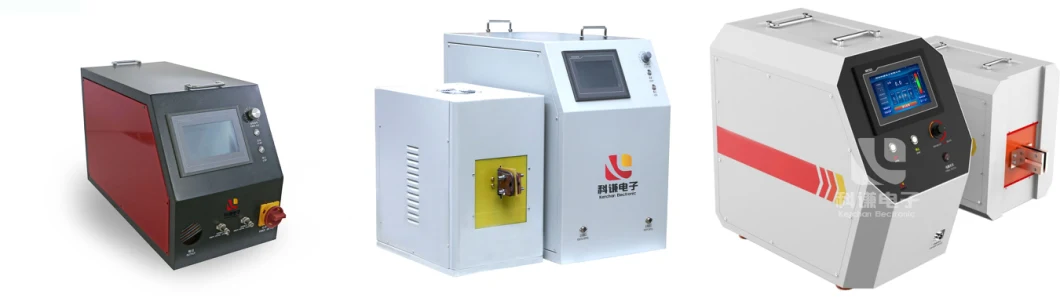

Hot Selling Stable Induction Heating Welding Forging Hardening Tempering Annealing Heat Treatment Equipment

1.Induction Heating Equipment

Adopt the IGBT as an inverter component, use the frequency automatic tracking technology always ensure the IGBT working in the ZCS(zero current) switch state. Adopt ZVT technology to make sure IGBT always working in the zero voltage transformation state. Both of the two technologies have improved the IGBT working frequency, increased the IGBT using life and stability, and also reduced the machine loss.

2.Induction Heating Equipment advantages and technical data:

•More reliable: the cabinet is well sealed, no failure all year, IGBT never burst.

•More Intelligent: Inverter power factor can reach 96%.

•More Intelligent: Control precision can reach 0.1%, all load can be automatically matching.

| Power range | 5-1000KW |

| Frequency range | 80-600KHZ |

| Voltage | 380V 460V 50HZ/60HZ |

| Power factor | >0.96 |

| Control Precision | 0.1% |

| Resonance Mode | Secondary Series resonance |

| Power Adjustment Mode | chopper power adjustment |

| Application field | Heat treatment(hardening, tempering, annealing, hardening&tempering), hot forging, melting, crystal growth, induction evaporation, forging, casting and so on. |

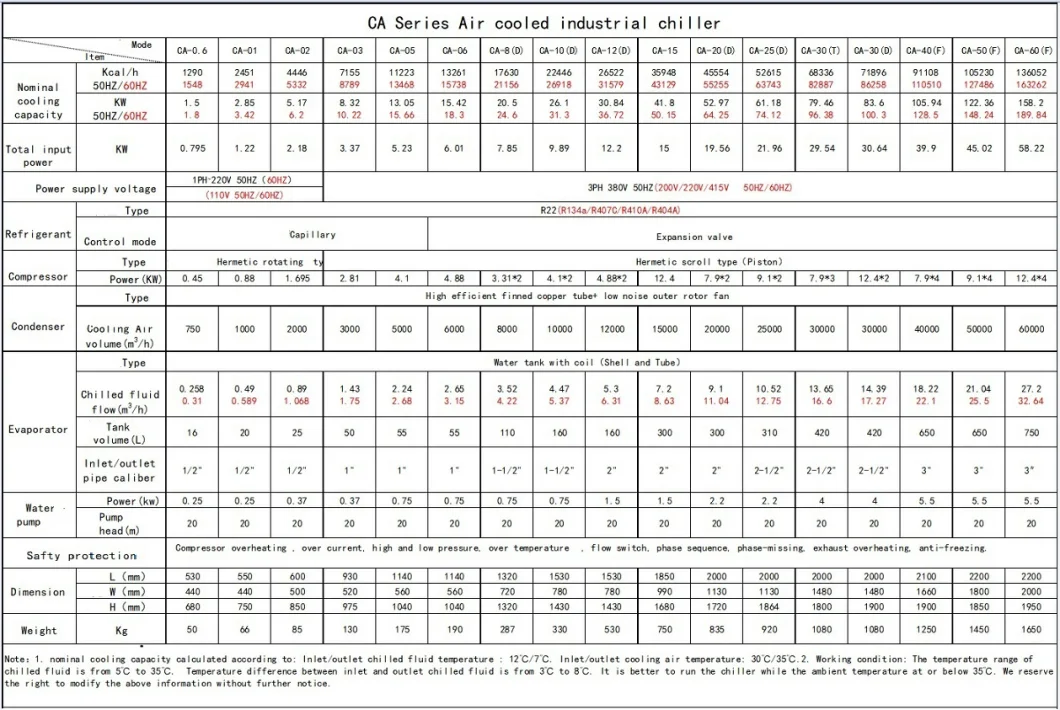

3. Industrial Chiller for Cooling induction Heating Equipment

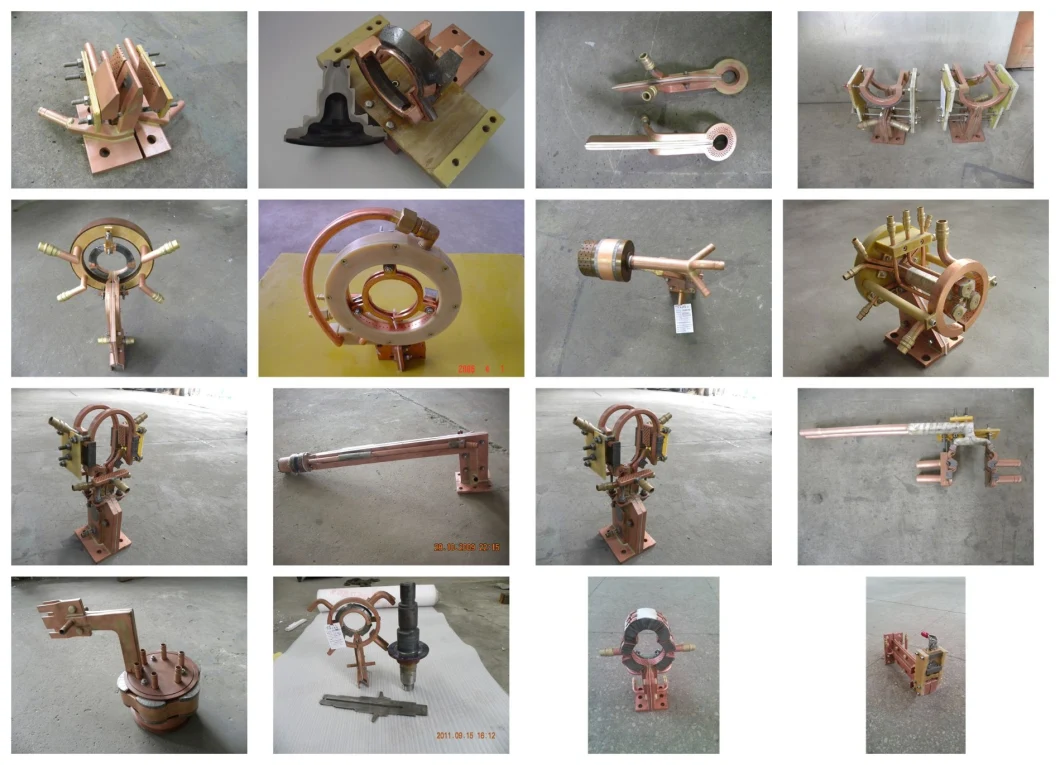

4. Induction Heating Equipment coil display:

5. induction Heating Equipment application cases display

Brazing & Welding

Hardening & Quenching

Forging & Tempering

Melting & Smelting

6. Induction Heating Equipment FAQ

1. What is your advantage to choose Zhengzhou Ketchan Electronic induction heating equipment?

We have a special team for after-sale service 24*7. We will take the video of the machine's running before delivery for your confirmation. We have got CE certificate which meets the European standard. Zhengzhou Ketchan Electronic takes quality as our culture.

2. If our machine meets fault, how could you help us to solve it?

The detailed fault description and photos should be informed to us. Our engineer will judge which part is trouble, then provide the advice and accessories list you need. If some problems can not be solved through communication, the engineer will be dispatched to debug onsite according to your requirements.

3. what is your warranty?

Our all machines' standard warranty is 12 months from the date of signing the turning over the document after commission.