Introduction of induction forging/heating machine:

1) LSW-120 induction heating machine with IGBT series parallel induction heating technology as the core.

2) Heating the workpiece surface and inside temperature to approximately equal by electromagnetic induction and conduction of heat.Introduction of induction heating/forging machine.

3) The principle is the magnetic induction heating principle.

4) Oscillation frequency selection: the larger the diameter of the workpiece is, the lower the oscillation frequency is needed.

5) Wttage selection: the larger the diameter of the workpiece is, or the higher the efficiency is required, the bigger wattage is needed.

Machine Pictures:

Features of induction heating/forging machine:

1) Siemens IGBT module and Inverting technologies of third generation been used; Higher reliability and lower maintenance cost.

2) High efficient: energy saving, environmental protection.

3) Heating fast: the fastest heating speed is less than 1 second, non-oxidizing and little deformation.

4) Widely application: can heating various of metal workpieces (according to different shapes of work pieces, replace removable induction coils).

5) Easy installation, simple operation, start fast, and little area occupied.

6) 100%duty cycle, continuous working ability at maximum power.

7) Low power consumption: can save about 40% energy than tradional HF tube furnace , save degree is relation with shapes of work pieces and induction coils.

Technical parameters of induction heating/forging machine:

| Main parameters of LSW-120 induction heating/forging machine | ||

| Model | LSW-120 | |

| Input voltage | 3 phase 380V, 50/60HZ or customized | |

| Max input current | 180A | |

| Max input power | 120KW | |

| Oscillation frequency | 15-30KHZ | |

| Duty cycle | 100% | |

| Cooling water flow | ≥ 0.2Mpa, ≥45L/min | |

| Cooling water pressure | ≥ 0.15-0.2MPa | |

| Weight | 230KG | |

| Dimension(L*W*H) | Generator | 770*620*1500mm |

| Transformer | 999*620*750mm | |

Application

Heating/forging:

Multifunction of induction heating/forging machine:

1) Heating/Hot forging: hot forging and hot rolling of fastener standard parts, automobile parts, hardware, cables, twist drill, etc.

2) Hardening/Quenching: for shafts, gears, chain wheels, castellated shafts, machine tools surfaces and bodies, automobiles, motorcycle parts, etc. quenching.

3) Welding/Brazing: brazing of diamond saw blade, alloy tools(lathe tool, reamer, milling tool) mining tools(drill bits, cutting picks) copper tubes, motor copper line, copper bars.

4) Metal smelting: gold, silver, copper, iron, aluminum and other metals (vacuum) melting, casting molding and evaporation coating.

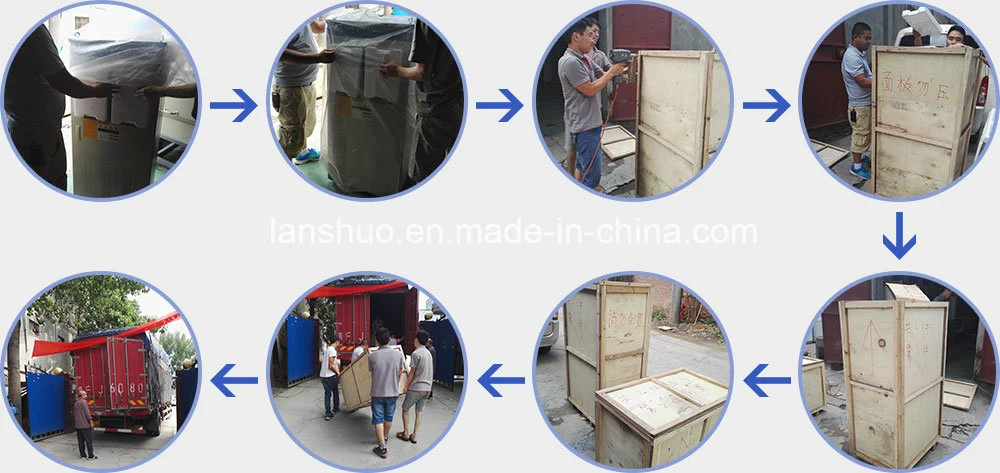

Packing&Delivery

Packaging: Induction heating/forging machine wrapped with plastic films and foam first, then put it into a standard export wooden case and fasten at last. (Can be customized if needed.)

Delivery: Within 7 working days after receiving your payment.

Our Company

1. Zhengzhou Lanshuo Electronics Co., Ltd is located in Zhengzhou National High & New Technology and Industrial Development Zone.

2. The company has 15-year experience in the R&D, design, production of high frequency and medium frequency induction heating machines. Products have won great reputation among clients.

3. Leading products include IGBT medium frequency induction heating equipment, IGBT super audio induction heating equipment, CNC quenching machine tool, IGBT medium frequency induction melting furnace, KGPS medium frequency induction melting furnace, open type water cooling tower, closed water cooling tower, etc.

4. Our products have been exported to the UK, Australia, Pakistan, Egypt, Singapore, India, Vietnam, Mexico, Uganda, Ukraine, Serbia, Russia, Germany, Turkey, South Korea, Malaysia, the Philippines and other countries.

5. We have senior engineers and technical researchers. Engineers are available to service overseas if needed.

If you have any interest in our products, please feel free to contact us. We will offer you the best service in the shortest time.

Certificate

Our Service

Pre-sale service:

1. Immediate reply to your inquiry.

2. Experienced sales answer all questions in fluent English.

3. Customized design is available.

4. Detailed information of our products, and our company if needed.

After-sale service:

1. Technical support, or alternative accessories if necessary.

2. Freely guide installation, commissioning and test run.

3. One year's warranty. Once there is a trouble within one year, professional engineers and sales will be promptly appointed to help.