LSW-80KW Induction Quenching Furnace

Quenching Furnace Product Description| Technical Parameters | |

| Model | LSW-80 |

| Working voltage (V/HZ) | 380/50 |

| voltage range (V) | 340-420 |

| Max input current (A) | 130 |

| Max input power (KW) | 80 |

| Oscillation frequency (KHZ) | 20-28 |

| Efficiency (%) | 90 |

| Duty cycle (%) | 100 |

| Cooling water flow:(control part)L/Main-MPa | 30-0.15 |

| Cooling water flow: (transfer part)L/Main-MPa | 40-0.15 |

| Weight: (control part)kg | 105 |

| Weight: (transferl part)kg | 116 |

| Dimension: (control part)cm | 60*48*136 |

| Dimension: (transfer part)cm | 50*80*58 |

Operation Pictures for Reference

Application

Our leading products with IGBT series parallel induction heating technology as the core. With super audio, medium frequency inverter power supply, PLC, CNC system automation control of cohesion. This kind of machine is mainly apply in metal heating/forging/hardening/quenching/welding/brazing/welting,etc.

Advantages

1) Using IGBT solid-state inverter technology, energy efficient, high output power.

2) Modular design, easy to install and operate, no debugging.

3) Protection function, high reliability and easy maintenance.

4) 100% duty cycle, 24 hours working in a row.

5) Can replace other heating methods (such as gas, coking coal, oil furnace, electric furnace, tube high frequency, etc.), energy saving.

6) Convenient to change furnace crucible for different material melting.

Certificate

Our Company

Our leading products with IGBT series parallel induction heating technology as the core. With super audio, medium frequency power supply, PLC, CNC system automation control of cohesion. With a strong dependent R&D capabilities with 12 years of industry experiences.

Our company's machine used six major application fields:(1) Metal forging, metal casting. (2) Induction brazing. (3) Induction hardening. (4)Induction annealing. (5) Quenching and high temperature tempering. (6) Metal heating in areas such high efficiency and energy saving equipment.

Our Service

1. Reply inquiry in 24 hours.

2. Experienced staffs answer all questions in fluent English.

3. Customized design is available.

4. Overseas on-site technicians service if required.

5. Special discount and protection of scales are provided to our distributor.

6. Long-term technical service.

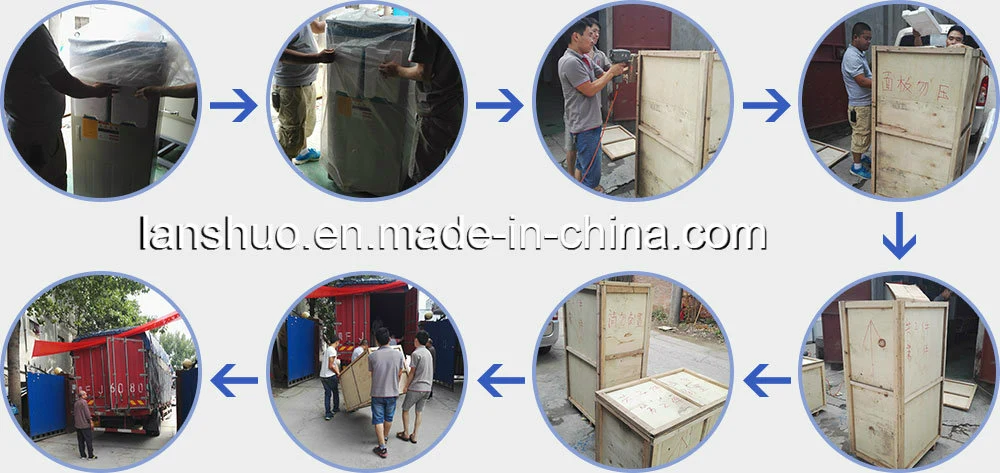

Packing & Delivery

FAQ

Q1. Why should I choose your company?

A. Our company has 12 years of industry experience, quality can be guaranteed.

B. With professional and technical personnel, first-class service personnel, a strong work team,

C. Reasonable price, products are exported America, Canada,Russia,Germany and other regions.

Q2. What about you MOQ?

We have reasonable price and according to your order quantity we will give appropriate discount.

Q3. How long the delivery time?

If we have products in stock, we will delivery as soon as possible. If not, we will arrang for you quickly and we guarantee delivery within 7-15 days.

Contact Us