100KW Induction Heating Machine With Hardening Tools Scan System

Introduction:

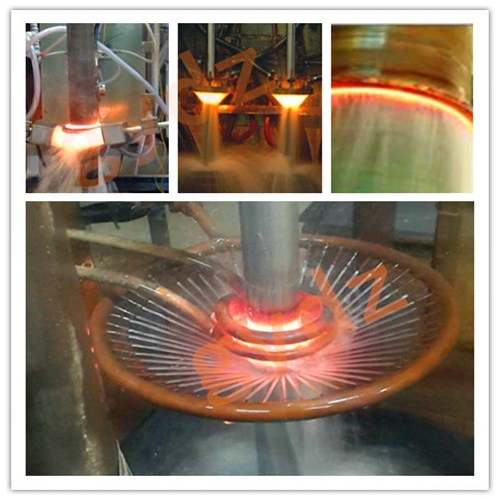

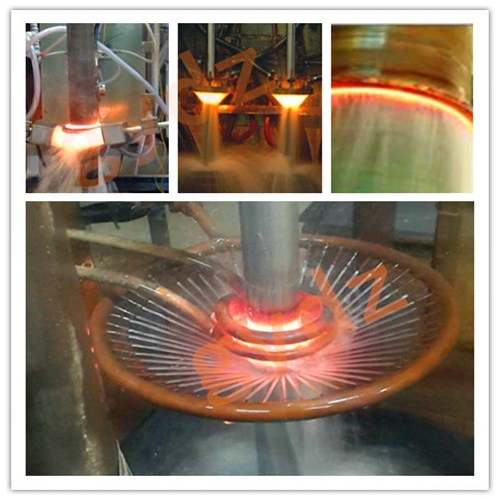

Induction hardening machine tools are used together with high and medium or super-audio frequency heating devices. For the purpose of conducting heat treatment of work pieces based on their own specificity the hardening equipment falls into: Hardening type, annealing type, tempering type, quenching type, welding and thermoforming type etc.

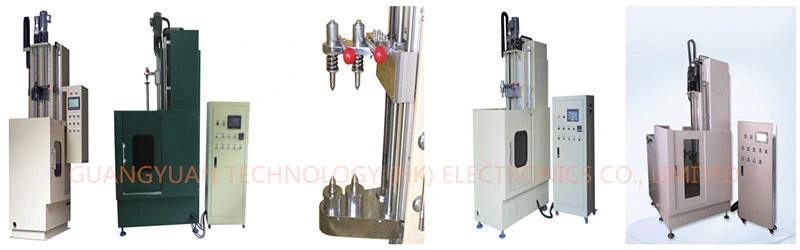

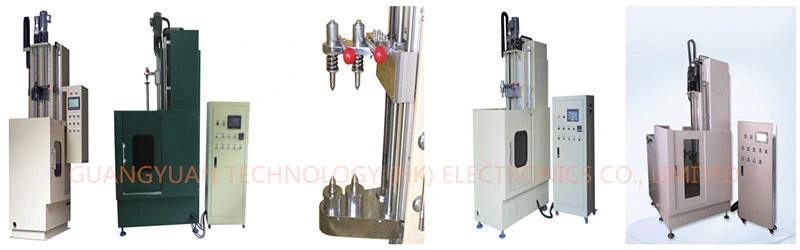

Hardening machine tools are generally classified as standard and special, the traditional ways are mechanic, hydraulic and compound. The control parts adopt PC control system, ple CNC and PLC system. Which ensure reliable program running, accurate position, easy operation, high automation. It can improve significantly the hardening quality.

Capability characteristic:

1. Adopt beeline bearing, high precision, little attrition, life length.

2. Ball bearing pole driving, serve electrical driving, high precision, life length.

3. Numerical control system is controlling, keyboard input, memory quenching procedure, working procedure is auto controlling.

4. Actualize shift, running calm, high orientation precision. Operation easily.

Parameter:

GY-CNC1000

GYS-100AB Parameter:

Introduction:

Induction hardening machine tools are used together with high and medium or super-audio frequency heating devices. For the purpose of conducting heat treatment of work pieces based on their own specificity the hardening equipment falls into: Hardening type, annealing type, tempering type, quenching type, welding and thermoforming type etc.

Hardening machine tools are generally classified as standard and special, the traditional ways are mechanic, hydraulic and compound. The control parts adopt PC control system, ple CNC and PLC system. Which ensure reliable program running, accurate position, easy operation, high automation. It can improve significantly the hardening quality.

Capability characteristic:

1. Adopt beeline bearing, high precision, little attrition, life length.

2. Ball bearing pole driving, serve electrical driving, high precision, life length.

3. Numerical control system is controlling, keyboard input, memory quenching procedure, working procedure is auto controlling.

4. Actualize shift, running calm, high orientation precision. Operation easily.

Parameter:

GY-CNC1000

| Maximum clamping parts length | 1000mm |

| Maximum quenching diamention | 100mm |

| Maximum workpiece weight | 50kg |

| Workpiece travel speed | 1-30mm/s |

| Workpiece updown speed | 120mm/s |

| Rotating speed | 1-200r/min |

| Cooling way | immersion ,spray, |

| Machine size after packing | 2440*1320*900MM |

| Operation | automatically or manually |

GYS-100AB Parameter:

| Model | GYS-100AB (Three phase) |

| Work power | 340V-430V |

| Maximum input current | 150A |

| Output power | 100KW |

| Fluctuating frequency | 10-50khz |

| Output current | 400-4000A |

| The flow rate of cooling water: | 0.08-0.16Mpa 10L/Min |

| Water temperature protection point | 50C |

| Product size | main : 790x695x1060mm |

| transformer : 865x420x650mm | |

| Net weight | main : 100kgs |

| transformer : 70kgs |