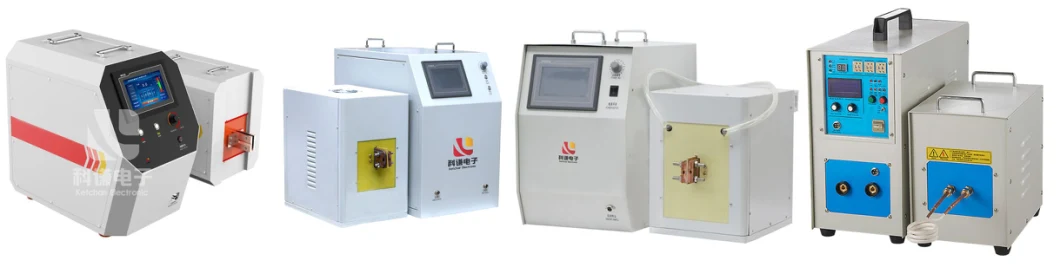

Robot CNC Induction Hardening Quenching Tempering Annealing Heat Treatment Machine Tool

1.Vernier caliper frame induction heat treatment machine functions and application:

2. Performance characteristics of the complete set of heat treatment equipment 3. CNC Induction Quenching Machine Tool Induction heating machine

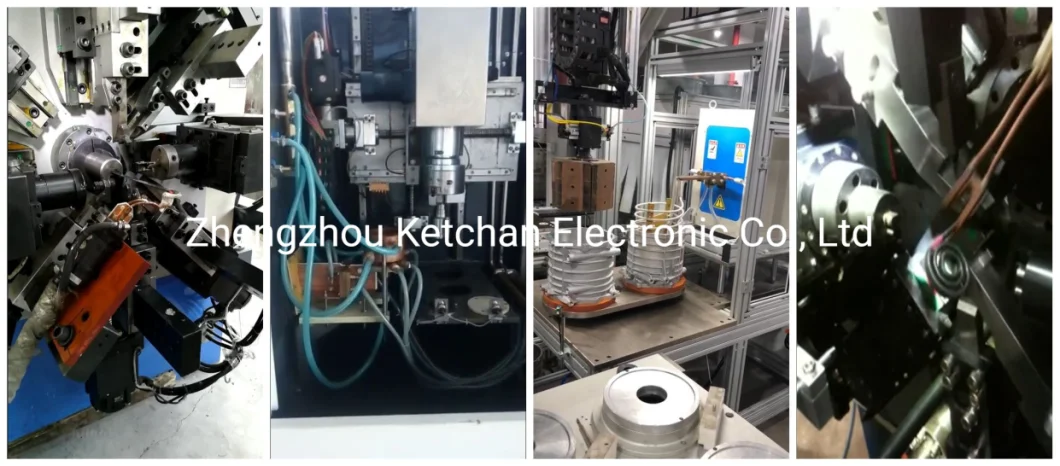

4. CNC Induction Quenching Machine Tool induction transformer

5. CNC Hardening machine tool induction coil

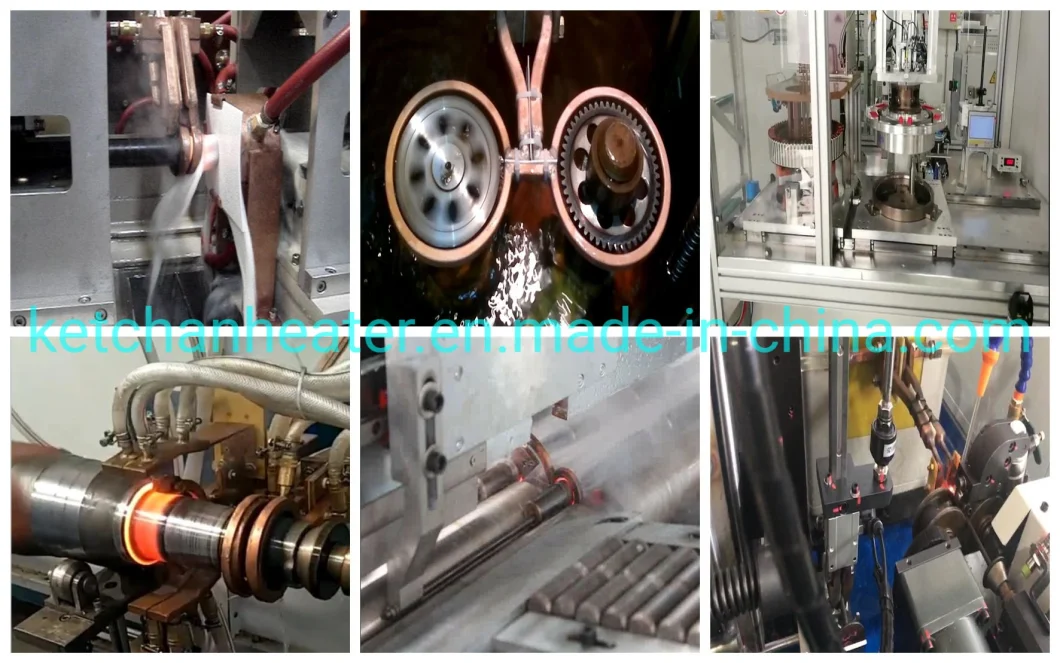

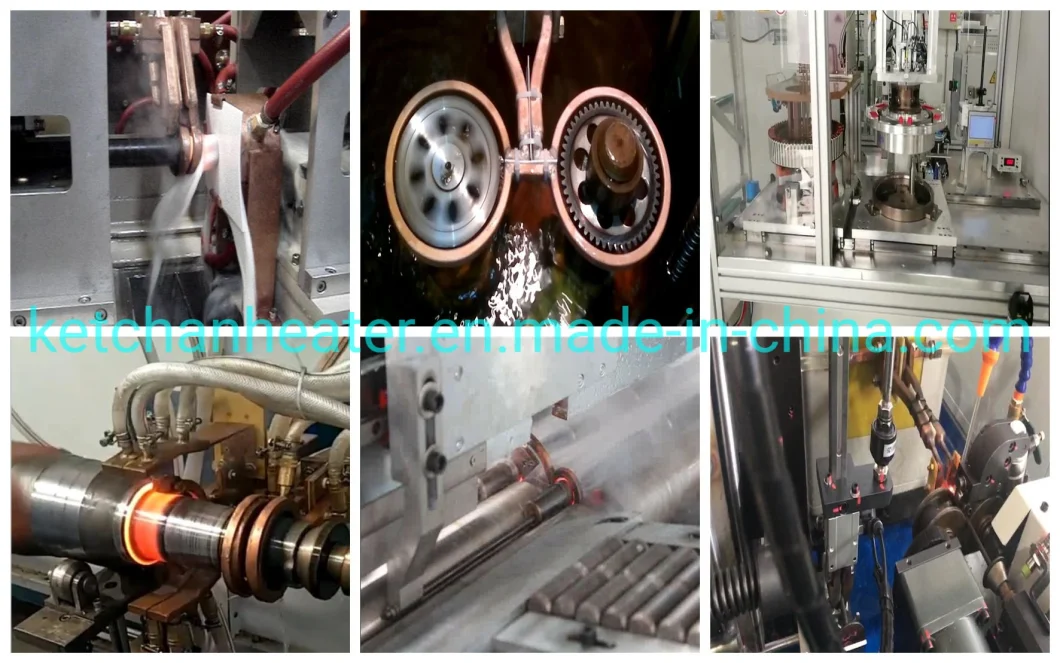

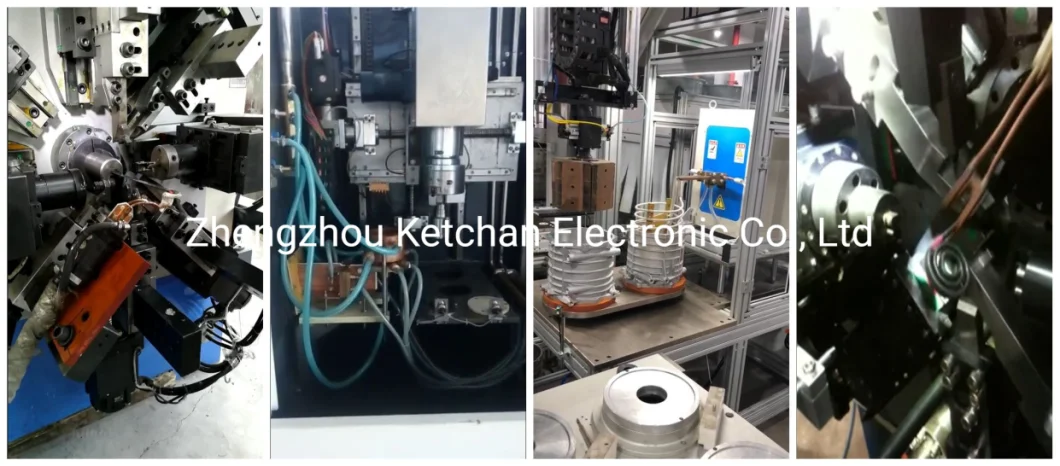

6.CNC Hardening machine tool Application cases

8. FAQ

1. What is your advantage to choose Ketchan induction heating system?

We have a special team for after-sale service 24*7. We will take the video of the machine's running before delivery for your confirmation. We have got CE certificate which meets the European standard. Ketchan takes quality as our culture.

2. If our machine meets fault, how could you help us to solve it?

The detailed fault description and photos should be informed to us. Our engineer will judge which part is trouble, then provide the advice and accessories list you need. If some problems can not be solved through communication, the engineer will be dispatched to debug onsite according to your requirements.

3. what is your warranty?

Our all machines' standard warranty is 12 months from the date of signing the turning over the document after commission.

- Adopt parts lifting and moving, transformer advance and retreat moving, spindle rotating structure.

- It has the functions of continuous scanning quenching, simultaneous quenching, segmenting continuous quenching, segmenting simultaneous quenching, inductor advance and retreat moving in place, induction heating quenching and so on.

- In the quenching process, it has the function of changing the moving speed and power of parts.Suitable for induction quenching of various transmission shafts, gears and other parts.

2. Performance characteristics of the complete set of heat treatment equipment

- The parts are driven by a servo motor and driven by a ball screw. The moving position is precisely controlled.

- Single/double center structure, clamping parts length can be electrically adjusted. Pneumatic top center automatic clamping.

- It can change the moving speed of parts and the power of power supply in real-time.

- With the induction heating condition monitoring system, it can display, record and store induction heat treatment process parameters in real-time.

- CNC system control, keyboard input, storage quenching program, work program automatic control.

- The process is easy to adjust, simple to operate and has perfect protection function.

- Quenching machine tool, power supply, and control system integrated design, according to the requirements of quenching parts, high, medium frequency power supply.

- Quenching medium circulating cooling system, equipment softening water circulating cooling system and machine tool matching installation

4. CNC Induction Quenching Machine Tool induction transformer

5. CNC Hardening machine tool induction coil

6.CNC Hardening machine tool Application cases

8. FAQ

1. What is your advantage to choose Ketchan induction heating system?

We have a special team for after-sale service 24*7. We will take the video of the machine's running before delivery for your confirmation. We have got CE certificate which meets the European standard. Ketchan takes quality as our culture.

2. If our machine meets fault, how could you help us to solve it?

The detailed fault description and photos should be informed to us. Our engineer will judge which part is trouble, then provide the advice and accessories list you need. If some problems can not be solved through communication, the engineer will be dispatched to debug onsite according to your requirements.

3. what is your warranty?

Our all machines' standard warranty is 12 months from the date of signing the turning over the document after commission.