Induction Heating Machine:

Advantage:

1 More than 21 years experience, stable and goods performance

2 CE certificated

3 Copperated with CHOW TAI FOOKS, Matsushita, Foxconn, Media, Gree and ZHIGAO Air conditioner.

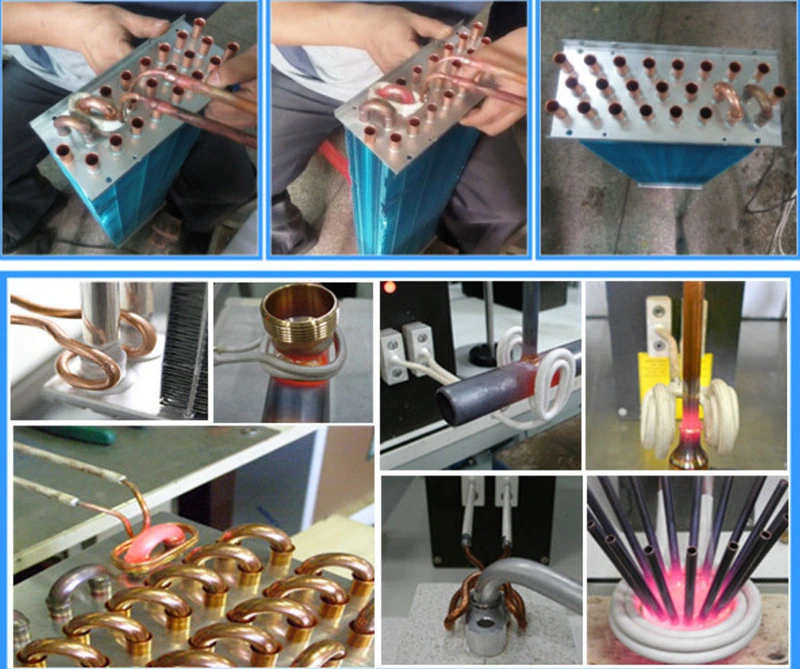

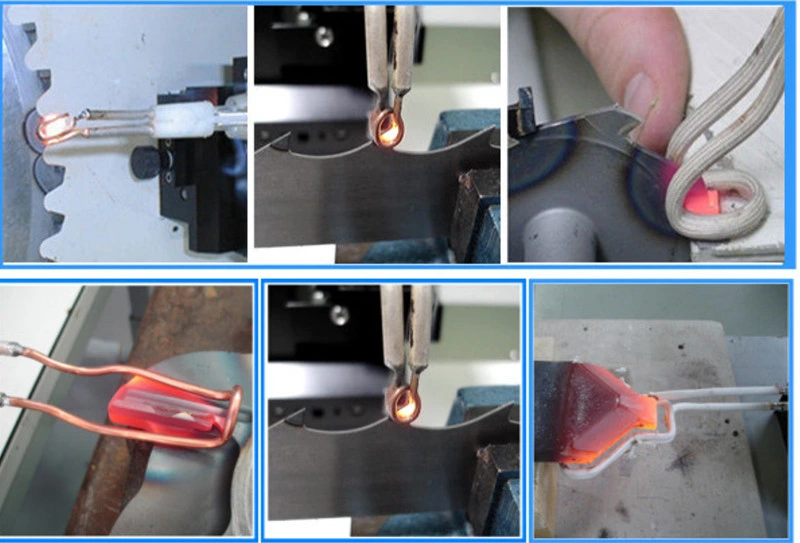

4 Suitable for a large range, heating, quenching, forging, melting, solding and so on.

5 One main part match two transformers, use the change switch to control let which one transformer to work, which one is prepare, save the time, improve the working effciency.

6 Each transformers have two transformer ratios, which good for connect different induction coils to work different workpiece.

Main characteristics:

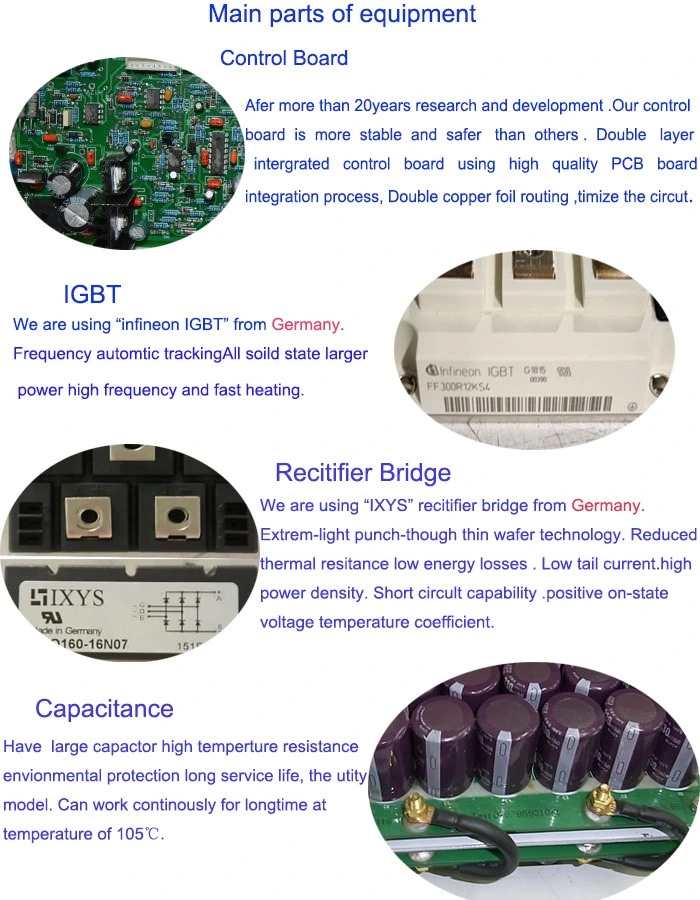

1 Siemens IGBT module and Inverting technologies of third generation been used; Higher reliability and lower maintenance cost.

2 100% Duty cycle, continuous working is allowed at maximum power output.

3 Display of heating power and heating current and oscillating frequency;

4 Simple to install, Installation can be done by unprofessional person very easily;

5 Light weight

6 Advantages of the model with timer: The power and the operating time of the heating period and the retain period can be preset respectively, to realize a simple heating curve, this model is suggested to use for batch production to improve the repeatability;

7 Constant current or constant power status can be selected accordingly to achieve higher heating efficiency;

Digital Type:

1 Front Panel use the LCD Touch Screen, Key and Power Switch, all digital display, can use Switch Signal( Electrical frequency signal) to control the machine start and stop, and control the power via PLC.

Visual Human-computer Interface makes the operator feel more intimate and intuitive. Because of its abundant industrial interfaces, it has stronger and more flexible matching ability with robots, various automation equipment and remoe control (unmanned) devices.

2 Induction Heating Machine have remote control function and adopt digital circuit control, power regulation can be adjusted from 0% to 100% resolution and digital PID temperature control module can be configured to set the target

temperature of workpiece(infrared temperature measurement orthermocouple temperature measurement) automatically. The accuracy of temperature control is + 1'C for power regulation in heating process.

3 There are 5 working model, manual, timer, temperature, Constant temperarure, section heating model.

1) Manual, On and stop in the Switch

2 ) Timer, setting heating time, after reach the heating time, then stop. Fixed Temperature: Set the heating temperature that we need it, when the reach to the temperature that we need it, then stop the machine.

3) Constant Temperature: Adjust the heating power automatic to keep the same temperature to the workpiece.

4) Section Heating model, there are 8(S1-S8) options, each section can set the heating power, timer, temperature or constant temperarture, temperature or constant temperature just can choose any one. Power as 0 means no need to heat, put the paramater that you need to set, if not choose that function then show"--

5) There are 9 (P1-P9)programs, which can memorize 9 different workpiece in the machine, and select programs by clicking P(P1-P9). Can save much time if you have many workpiece in one machine, you can choose the programs (P1-P9) to fast working.

4 Infrared Thermometer can As Options.

| Type | HF-15AB/15A |

| Work Power | 220v simple phase 50-60hz |

| The range of operating voltage | 340-430AC |

| Output power | 15KW |

| Input current | 36A |

| Fluctuating frequency | 30-100khz |

| Timing (Heat time, Retain time, Cool time) | 1-99S |

| The flow rate of cooling water | 0.15 Mpa 7.6L/Min |

| Water temperature protection point | 40centidegree |

| Duty cycle | 100% (40degree room temperature) |

| Weight | 35Kg |

| Size | 640*280*550mm |

| Type | HF-15AB/15A |

| Work Power | 3*380v/415v/440v/480v 50-60hz |

| The range of operating voltage | 340-430AC |

| Output power | 15KW |

| Input current | 13A |

| Fluctuating frequency | 30-100khz |

| Timing (Heat time, Retain time, Cool time) | 1-99S |

| The flow rate of cooling water | 0.15 Mpa 7.6L/Min |

| Water temperature protection point | 40centidegree |

| Duty cycle | 100% (40degree room temperature) |

| Weight | 35Kg |

| Size | 640*280*550mm |

| Type | HF-25AB/25A |

| Work Power | 3*380v/415v/440v/480v 50-60hz |

| The range of operating voltage | 340-430V AC |

| Output power | 25KW |

| Input current | 26A |

| Fluctuating frequency | 30-80khz |

| Timing (Heat time, Retain time, Cool time) | 1-99S |

| The flow rate of cooling water | 0.15 Mpa 9L/Min |

| Water temperature protection point | 40centidegree |

| Duty cycle | 100% (40degree room temperature) |

| Weight | Mainparts:42Kg Transformer:21kg |

| Size | Main Parts:640*280*550mm Transformer:450*250*380mm |

| Type | HF-40AB |

| Work Power | 3*380v/415v/440v/480v 50-60hz |

| The range of operating voltage | 340-430V AC |

| Output power | 40KW |

| Input current | 40A |

| Fluctuating frequency | 30-80khz |

| Timing (Heat time,Retain time,Cool time) | 1-99S |

| The flow rate of cooling water | 0.15 Mpa 10L/Min |

| Water temperature protection point | 40centidegree |

| Duty cycle | 100% (40degree room temperature) |

| Weight | Mainparts:42Kg Transformer:32kg |

| Size | Main Parts::640*280*550mm Transformer: 510*270*440mm |

| Type | HF-65AB |

| Work Power | 3*380v/415v/440v/480v 50-60hz |

| The range of operating voltage | 340-430V AC |

| Output power | 65KW |

| Input current | 60A |

| Fluctuating frequency | 30-80khz |

| Timing (Heat time,Retain time,Cool time) | 1-99S |

| The flow rate of cooling water | 0.15 Mpa 11L/Min |

| Water temperature protection point | 40centidegree |

| Duty cycle | 100% (40degree room temperature) |

| Weight | Mainparts:45Kg Transformer:38kg |

| Size | Main Parts:640*350*550MM Transformer: 510*270*440MM |

| Type | HF-80AB |

| Work Power | 3*380v/415v/440v/480v 50-60hz |

| The range of operating voltage | 340-430V AC |

| Output power | 80KW |

| Input current | 75A |

| Fluctuating frequency | 30-80khz |

| Timing (Heat time,Retain time,Cool time) | 1-99S |

| The flow rate of cooling water | 0.15 Mpa 11L/Min |

| Water temperature protection point | 40centidegree |

| Duty cycle | 100% (40degree room temperature) |

| Weight | Mainparts:55Kg Transformer:42kg |

| Size | Main Parts:640*350*550MM Transformer: 510*270*440MM |

| Type | HF-90AB |

| Work Power | 3*380v/415v/440v/480v 50-60hz |

| The range of operating voltage | 340-430V AC |

| Output power | 90KW |

| Input current | 90A |

| Fluctuating frequency | 30-80khz |

| Timing (Heat time,Retain time,Cool time) | 1-99S |

| The flow rate of cooling water | 0.15 Mpa 13L/Min |

| Water temperature protection point | 40centidegree |

| Duty cycle | 100% (40degree room temperature) |

| Weight | Mainparts:58Kg Transformer:45kg |

| Size | Main Parts:640*350*550MM Transformer: 510*280*450MM |

| Type | HF-100AB |

| Work Power | 3*380v/415v/440v/480v 50-60hz |

| The range of operating voltage | 340-430V AC |

| Output power | 100KW |

| Input current | 100A |

| Fluctuating frequency | 30-80khz |

| Timing (Heat time,Retain time,Cool time) | 1-99S |

| The flow rate of cooling water | 0.15 Mpa 15L/Min |

| Water temperature protection point | 40centidegree |

| Duty cycle | 100% (40degree room temperature) |

| Weight | Mainparts:85Kg Transformer:78kg |

| Size | Main Parts:850*510*750MM Transformer: 580*345*520MM |

Pre-sale service:

1. recommend the most suitable machine for customers, according to their requirements.

2. Inquiry and consulting support.

3. Sample testing support.

4. View our Factory.

In-sale service:

1. Strictly manufacture the machine, according to relevant technical standards.

2. Take run test, according to relevant equipment test run regulations.

3. Strictly check up the machine, before delivery

4. Delivery on time.

After-sale service:

1. Warranty time: Within 18 months from the date of delivering, 12months from date of receiving.

2. Within warranty all parts are free for customer, any fault caused by non-artificial reason, any quality problems such as design, manufacture, or procedure occurs, We shall provide replacement parts after detecting the faults.

3. If any big quality problems occurs out of the guarantee period, we will send maintenance

technician to provide visiting service after checking with the customer and charge for a favorable price.

5. We will provide a lifetime cost price to the buyer with the materials and spare parts used in system operation, equipment maintenance.

6. The above mentioned are only basic aftersale service requirements,we will make more promises related to quality assurance and operation guarantee.