Production introduction

Structural principle and characteristics :

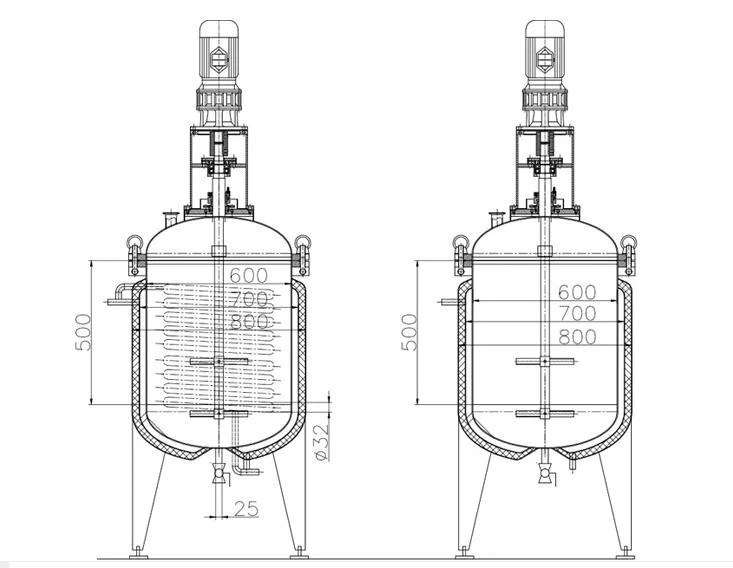

1.The reactor is composed of a pot body, a lid, a stirrer, a jacket, support, and a transmission device, a shaft sealing device, etc.

2.The material and openings can be customization .

3.The heating forms include electric heating/water heating (or cooling).

4. Jacket type is conventional jacket ,full jacket and coil jacket

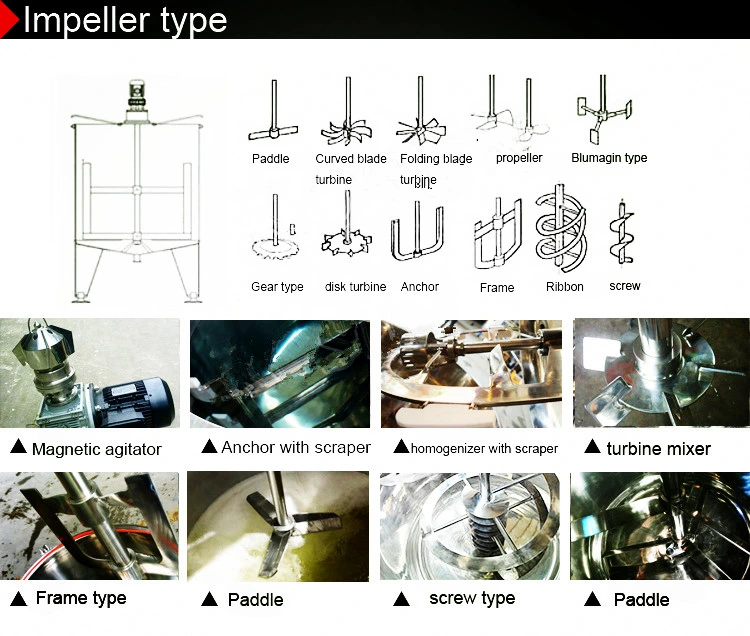

5. Stirring types are generally paddle type, anchor type, frame type, spiral type, and scraped wall type.

6.High-speed types include discrete impeller type, turbine type, high shear type, and propeller type for customers to choose according to the process.

7.The transmission forms include ordinary motors, explosion-proof motors, electromagnetic speed-regulating motors, etc.

Main Features

1.The inner tank body is made of stainless steel (SS316L/304/2507/2205) according to the process requirements. It can be cleaned online by CIP and sterilized by SIP.

- Appropriate diameter-to-height ratio design,

-customized mixing device as required;

2. mixing shaft seal adopts pressure-resistant sanitary mechanical sealing device to maintain working pressure in the tank and prevent unnecessary leakage and material loss caused by material leakage in the tank

3.The supporting type adopts hanging ear type or floor leg type according to the operation requirements.

Composition

The whole reaction equipment can be equipped with condenser, condensate receiver, circulation pump, pipes, etc, accodring to customer's requirement and technology product processing.

The tank body can be equipped with the CIP automatic rotary spray cleaning ball, thermometer, manhole, pressure gauge, explosion-proof inspection light, sight glass, quick open type feeding inlet and etc, ensuring convenient operation and complying with the GMP standard.

Certifications

Our Collaborations

Trade Shows

Packaging & Shipping

KEAN has the highly professional packaging services and expertise to meet your most demanding packaging needs, aiming to bring your products to your location in less time and with higher quality.

FAQ

1. Is your company a factory or trading company?

KEAN is a highly professional manufacturing entity focusing on fabricating pressure vessel and tanks, integrated bioengineering fermentation systems, cell culture systems, large infusion systems, fluid handling system, CIP/SIP systems.

2. Can you product as specific size?

Definitely we can. Our products are customized as per your requirements.

3. Can I have samples to test?

Yes, we are pleased to supply samples test report issued by renowned authority and ensure quality. Our products are fabricated stringently in compliant with ISO, ASME BPE, cGMP international codes.

4. Do you have any MQQ limitation?

Our MQQ is 1 PC to supply new customers.

5. How long is the lead time?

Normally it takes 5-6 weeks for stainless steel tanks, and 7-10 weeks for integrate modular systems.

6. Do you provide after-sales service?

Yes, we are committed to offering highly professional and real-time after-sales service. We have many professional and dedicated engineers available ensuring a holistic service to our highly-respected customers.

Contact us for more information.

Kelly

KEAN ZhuoLu Technical Equipment Co.,ltd

http://kean-z.en.made-in-china.com