High Efficiency IGBT Induction Heating Machine for End Forging (JLC-80)

Main Feature:

- It adopts the IGBT inverter circuit in parallel connection, which has high load adaptability.

- The comprehensive full load design is available for 24-hour continuous operation.

- The digital phase locked realizes following frequency automatically.

- Design in modules. It is installed facility and use conveniently without debugging..

- The perfect protection function, insuring the reliability and easily maintaining of the equipments.

- The technique of converting frequency by resonance promotes efficiency of whole equipment by over 95%.

- Economy and environment protection, it can replace of gas/coal/electronic tube induction heating machine.

Technical Parameters:

Spare Parts for JLC-80KW

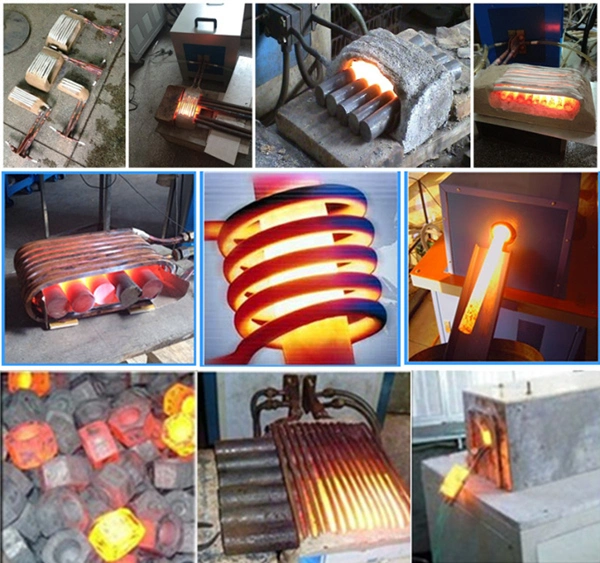

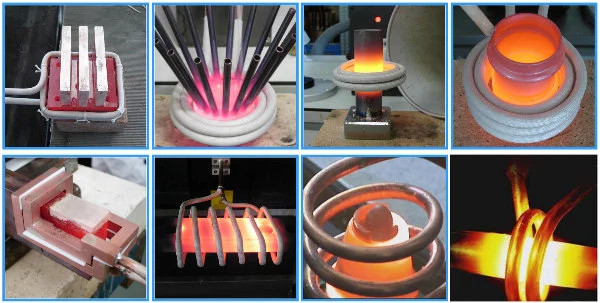

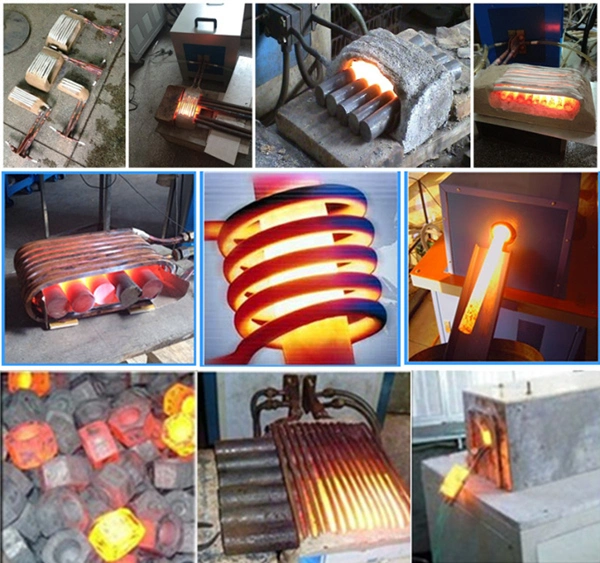

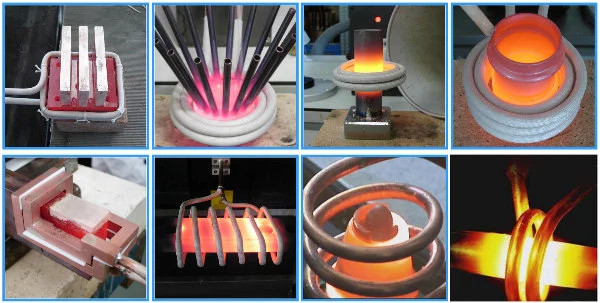

Photos of JLC-80KW Machine

Applications: Forging, Heat treatment (Quenching), Welding etc.

1.Forging Molding

M.F. forging furnace is used for the heating of bars and rods larger than Φ12, the material can be steel, stainless steel, copper, brass ,aluminium and so on. The heating can be the whole rod, end of the rod or middle part of the rod.

Application Examples:Fasteners, Hardware tools, Automobile and motorcycle accessories, Rigging, Pipe fittings, Twist drill, Atlas, Table, Mould parts, Standard parts, Handicrafts, Machinery parts, Brass lock, Lock, Rivets, Other hardware and metal accessories.

Main models and heating ability:

2.Heat treatment:such as Quenching, Annealing

Heat treatment process is the metal work-pieces heated to a certain temperature, obtained different matrix organization after different ways of cooling, so that to achieve the required mechanical properties (material harder or softer), such as quenching, annealing, etc.

Applications Examples: Shaft, Shaft core, Plate, Gear, Sprocket, Steel belt, Machine tool accessories, Guide rail, Hardware tools, Small mold, Mold accessories, CAM, Automobile and motorcycle accessories, Scissors, Garden shears blade, Chuck, mechanical parts, Stainless steel products, Cistern, Kitchen ware, Golf head, Clubs, Steel tube, Furniture fittings and Other related products.

3.Brazing, Welding, Soldering

Brazing is a fusion and solidification process which refers to the use of magnetic field induction heating to make the temperature of metal materials junction reach the melting point of welding, or the temperature of metal materials to reach between nonmetallic material.

(1). Any industry of add welding material connection.

Such as: Cutting tools ( Turning, Milling cutter, Woodworking tools, Serrated blade, Shoe materials, Diamond tool, Deep hole drilling, Drilling etc.), Faucets, Bathroom accessories, Showers, Coal drill, Drill bit, Terminal blocks, Furniture fittings, Refrigeration equipment, Pad tube, Heating plate, Egg beater, Lighting accessories, Branch distributor, Bicycle up and down the fork iron, Copper pieces, Aluminum, Stainless steel.

(2). Do not add welding material connection.

Such as: Computer radiator core and copper core, Motor rotor and shaft, Horn net preparetions, Hanger hook, Copier carbon brush melt, Aluminum-plastic pipe, Compound preparetions kettle, Tool shank cure, Tableware curing rubber handle, Battery pole ear forming, Aluminum foil sealing etc.

Package

Company information:

Dongguan Jinlai Electromechanical Device Co.,Ltd., founded in 1996, which is engaged in R&D,

production andsale of solid Induction heating machine professionally. Several senior experts of induction heating equipment gathered here, who initiate the induction heating machines with environmental protection and highly effective energy conservation, positively and diligently.

FAQ

China Supplies Induction Heating Power Supply

Questions and Answers:

1. Which countries your products are exported to?

Our products are sold all over the world and with related certifications.

2.How about the warranty?

All our products have one year quality warranty, during the warranty time, the spare parts replacement is free. And we provide life long time technical support and other assistance.

3.How to install your machine?

We have paper installation instructions and videos, we will teach till you learn it.

4. Which export port you use?

Any China port, commonly we will use Shenzhen ,Guangzhou ,Hongkong port, it can appoint as you like.

5.How about the payment terms and delivery time ?

Payment terms for small machines: 100% T/T/ Western Union/Cash in advance.

The big machines and big amount: 30% deposit,70% before shipment (we will shoot total delivering process for customer's confirmation)and the related papers. You can pay by T/T,L/C, Western Union or other ways.

The small machine delivery time is within 7 days, the bigger one takes about 15days,we will delivery goods on time.

6.If I have paid but can not receive the goods, how should I do?

Alibaba international website is a famous trade platform and has been mature those years ,every supplier on it has paid large integrity fund,and we have Chinese business licenses which can be checked on China official website or we can show it to you,so that situation will never appear, please be assured.

7.Is your goods has ISO9001 or CE certificate ?

Yes, all our goods has ISO and CE certificate. All machines are high quality goods.

8.What is your nature of your company:dealer or factory ?

We are manufacturer and have a big factory ,warmly welcome to visit our factory and contact us.

| Model | JLC-80KW | |

| Input power desire | 3 phase 380V 50/60HZ | |

| Oscillate power max | 80KW | |

| Max input current | 135A | |

| DC current | 150A | |

| Oscillate frequency | 10-30KHZ | |

| Timing | 1M-99.99M 1S-99.99S 0.01S-99.99S | |

| Cooling water desire | 0.4Mpa | |

| Duty cycle | 100% 40°C | |

| Dimensions(L*W*H) | Generator | 830*620*1510mm |

| transformer | 730*440*560mm | |

| Net weight | 80kg/55kg | |

| Cable length | 2-6(Meters) | |

Spare Parts for JLC-80KW

| Item | Name of machine or parts | Specification | Amount |

| 1 | JLC-80KW Generator | - | 1 pcs |

| 2 | JLC-80KW Transformer | - | 1 pcs |

| 2 | Foot switch | 3 core | 1 pcs |

| 3 | Induction Coils | - | 2 sets |

| 4 | Coil connect pole | - | 2 sets |

| 5 | Instruction Manual | - | 1 pcs |

| 6 | Guarantee card | - | 1 pcs |

| 7 | Products certificate | - | 1 pcs |

Photos of JLC-80KW Machine

Applications: Forging, Heat treatment (Quenching), Welding etc.

1.Forging Molding

M.F. forging furnace is used for the heating of bars and rods larger than Φ12, the material can be steel, stainless steel, copper, brass ,aluminium and so on. The heating can be the whole rod, end of the rod or middle part of the rod.

Application Examples:Fasteners, Hardware tools, Automobile and motorcycle accessories, Rigging, Pipe fittings, Twist drill, Atlas, Table, Mould parts, Standard parts, Handicrafts, Machinery parts, Brass lock, Lock, Rivets, Other hardware and metal accessories.

Main models and heating ability:

| models | Max. Input Power | Heating ability of normal material | ||

| Steel or S.S to 1100 degree | Copper or brass to 700 degree | Aluminium to 500 degree | ||

| JLZ-35 forging furnace | 35KW | 1.25 KG/min | 1.75 KG/min | 1.46 KG/min |

| JLZ-45 forging furnace | 45KW | 1.67 KG/min | 2.33 KG/min | 1.87 KG/min |

| JLZ-70 forging furnace | 70KW | 2.5 KG/min | 3.5 KG/min | 2.92 KG/min |

| JLZ-90 forging furnace | 90KW | 3.33 KG/min | 4.67 KG/min | 3.75 KG/min |

| JLZ-110 forging furnace | 110KW | 4.17 KG/min | 5.83 KG/min | 4.58 KG/min |

| JLZ-160 forging furnace | 160KW | 5.83 KG/min | ------- | 6.67 KG/min |

| JLZ-200 forging furnace | 200KW | 9.0 KG/min | ------- | 8.50 KG/min |

2.Heat treatment:such as Quenching, Annealing

Heat treatment process is the metal work-pieces heated to a certain temperature, obtained different matrix organization after different ways of cooling, so that to achieve the required mechanical properties (material harder or softer), such as quenching, annealing, etc.

Applications Examples: Shaft, Shaft core, Plate, Gear, Sprocket, Steel belt, Machine tool accessories, Guide rail, Hardware tools, Small mold, Mold accessories, CAM, Automobile and motorcycle accessories, Scissors, Garden shears blade, Chuck, mechanical parts, Stainless steel products, Cistern, Kitchen ware, Golf head, Clubs, Steel tube, Furniture fittings and Other related products.

3.Brazing, Welding, Soldering

Brazing is a fusion and solidification process which refers to the use of magnetic field induction heating to make the temperature of metal materials junction reach the melting point of welding, or the temperature of metal materials to reach between nonmetallic material.

(1). Any industry of add welding material connection.

Such as: Cutting tools ( Turning, Milling cutter, Woodworking tools, Serrated blade, Shoe materials, Diamond tool, Deep hole drilling, Drilling etc.), Faucets, Bathroom accessories, Showers, Coal drill, Drill bit, Terminal blocks, Furniture fittings, Refrigeration equipment, Pad tube, Heating plate, Egg beater, Lighting accessories, Branch distributor, Bicycle up and down the fork iron, Copper pieces, Aluminum, Stainless steel.

(2). Do not add welding material connection.

Such as: Computer radiator core and copper core, Motor rotor and shaft, Horn net preparetions, Hanger hook, Copier carbon brush melt, Aluminum-plastic pipe, Compound preparetions kettle, Tool shank cure, Tableware curing rubber handle, Battery pole ear forming, Aluminum foil sealing etc.

Package

Company information:

Dongguan Jinlai Electromechanical Device Co.,Ltd., founded in 1996, which is engaged in R&D,

production andsale of solid Induction heating machine professionally. Several senior experts of induction heating equipment gathered here, who initiate the induction heating machines with environmental protection and highly effective energy conservation, positively and diligently.

Our Services:

1. Pre-sale service:

- Recommend the most suitable machine for customers, according to their requirements.

- Inquiry and consulting support.

- Sample testing support.

- View our Factory.

2. In-sale service:

- Strictly manufacture the machine, according to relevant technical standards.

- Take run test, according to relevant equipment test run regulations.

- Strictly check up the machine, before delivery

- Delivery on time.

3. After-sale service:

- 12 months warranty period

- Within one year free warranty, any fault caused by non-artificial reason, any quality problems such as design, manufacture, or procedure occurs, Jinlai shall provide replacement parts after detecting the faults.

- If any big quality problems occurs out of the guarantee period, Jinlai will send maintenance

- Technician to provide visiting service after checking with the customer and charge for a favorable price.

- Jinlai will provide a lifetime favorable price to the buyer with the materials and spare parts used in system operation, equipment maintenance.

- The above mentioned are only basic after-sale service requirements, we will make more promises related to quality assurance and operation guarantee mechanism.

FAQ

China Supplies Induction Heating Power Supply

Questions and Answers:

1. Which countries your products are exported to?

Our products are sold all over the world and with related certifications.

2.How about the warranty?

All our products have one year quality warranty, during the warranty time, the spare parts replacement is free. And we provide life long time technical support and other assistance.

3.How to install your machine?

We have paper installation instructions and videos, we will teach till you learn it.

4. Which export port you use?

Any China port, commonly we will use Shenzhen ,Guangzhou ,Hongkong port, it can appoint as you like.

5.How about the payment terms and delivery time ?

Payment terms for small machines: 100% T/T/ Western Union/Cash in advance.

The big machines and big amount: 30% deposit,70% before shipment (we will shoot total delivering process for customer's confirmation)and the related papers. You can pay by T/T,L/C, Western Union or other ways.

The small machine delivery time is within 7 days, the bigger one takes about 15days,we will delivery goods on time.

6.If I have paid but can not receive the goods, how should I do?

Alibaba international website is a famous trade platform and has been mature those years ,every supplier on it has paid large integrity fund,and we have Chinese business licenses which can be checked on China official website or we can show it to you,so that situation will never appear, please be assured.

7.Is your goods has ISO9001 or CE certificate ?

Yes, all our goods has ISO and CE certificate. All machines are high quality goods.

8.What is your nature of your company:dealer or factory ?

We are manufacturer and have a big factory ,warmly welcome to visit our factory and contact us.

Superaudio Frequency Series (10-30KHZ)

| Model | JLC-30 | JLC-50 | JLC-60 | JLC-80 | JLC-120 |

| Input power desire | 3 phase 380V 50/60HZ | ||||

| Oscillate power max | 30KW | 50KW | 60KW | 80KW | 120KW |

| Max input current | 48A | 63A | 90A | 135A | 195A |

| DC current | 60A | 80A | 120A | 150A | 250A |

| Oscillate frequency | 10-30KHZ | 10-30KHZ | 10-30KHZ | 10-30KHZ | 10-30KHZ |

| Timing | 1M-99.99M 1S-99.99S 0.01S-99.99S | 1M-99.99M 1S-99.99S 0.01S-99.99S | 1M-99.99M 1S-99.99S 0.01S-99.99S | 1M-99.99M 1S-99.99S 0.01S-99.99S | 1M-99.99M 1S-99.99S 0.01S-99.99S |

| Cooling water desire | 0.2Mpa | 0.3Mpa | 0.3Mpa | 0.4Mpa | 0.5Mpa |

| Duty cycle | 100% 40°C | ||||

| Net weight | 60kg/30kg | 65kg/45kg | 70kg/45kg | 80kg/55kg | 110kg/90kg |

| Cable length | 2-6(Meters) | 2-6(Meters) | 2-6(Meters) | 2-6(Meters) | 2-6(Meters) |